Vinyl flooring is a versatile and stylish choice for any home or commercial space. However, achieving a flawless finish requires careful preparation and understanding of the product’s construction. At Clarkes Carpets, we provide not only high-quality vinyl flooring but also expert guidance on installation to ensure your floors look perfect and perform exceptionally well.

Clarkes Carpets Vinyl Flooring Options

Preparation: The Foundation of a Perfect Vinyl Flooring Installation

Proper preparation is crucial when installing vinyl flooring. Here are the key steps to prepare your subfloor:

1. Ensure a Dry, Sound, and Level Subfloor

Vinyl flooring is relatively thin, and its ability to reflect light can quickly reveal any imperfections. A subfloor that is not dry, sound, and level can cause wear issues and detract from the overall appearance of the floor.

2. Preparing Wooden/MDF Subfloors

For existing wooden or MDF floors, you may need to lay a plywood underlay up to 6mm thick. The joints between the plywood sheets should be skimmed or taped to create a smooth surface.

3. Preparing Non-Wood Subfloors

Non-wood subfloors often require a self-leveling screed to ensure a suitable base for the vinyl flooring. Depending on the moisture levels of the subfloor, a damp-proof membrane may also be necessary to prevent moisture from affecting the vinyl.

4. Using Rigid Core Products

New rigid core vinyl products are less flexible and can be laid more easily over existing floors, even if they are not perfectly level. This reduces preparation time and effort while still achieving a smooth, attractive finish.

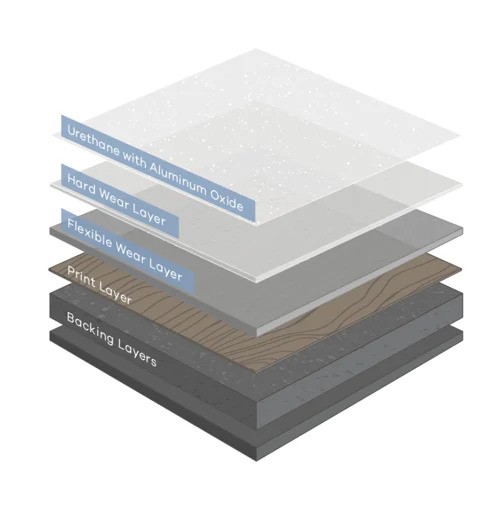

Understanding Luxury Vinyl Tiles Construction

Luxury Vinyl Tiles (LVT) are engineered for durability and realism. Here’s a breakdown of their construction:

1. Top Coating

The top layer is a polyurethane or aluminum oxide coating that provides protection against scratches and stains. This layer also enhances the anti-slip properties of the flooring, making it safe for high-traffic areas.

2. Wear Layer

The wear layer is crucial for the performance and resilience of the flooring. For heavy wear areas, a 0.3mm (12 mil) wear layer is recommended. Commercial installations may require thicker wear layers, such as 0.5mm or even 0.7mm, to withstand more intense usage. The wear layer thickness directly influences the product’s warranty and guarantees.

3. Decor Layer

This layer features the printed design of the vinyl flooring, typically a high-resolution photographic print on paper or film. Some LVT products have the image printed directly onto the surface, but this can result in lower image definition and different wear characteristics.

4. PVC and Fiberglass Layers

The construction of LVT involves a combination of PVC (polyvinyl chloride) layers for strength and flexibility, and fiberglass layers for structural stability. These layers form a ‘sandwich’ that provides durability and performance. The click system, if present, is also integrated into these layers. Many products use a mix of recycled vinyl for cost-effectiveness and virgin PVC for enhanced longevity and stability.

5. Rigid Core LVT

Rigid core LVT features a less flexible PVC layer that offers maximum stability. This type of LVT can be installed over existing, less even flooring without showing imperfections, thereby avoiding wear problems associated with traditional vinyl.

6. Base (or Backing) Layer

The base layer, made of high-density PVC, varies depending on the installation requirements. It is designed to take adhesive for glue-down installations or serve as an underlay for loose-lay and click installations.

LVT Installation Methods

There are several installation methods for vinyl flooring, each suited to different needs and preferences:

1. Dry Back

This method involves gluing the sheets or tiles to the subfloor. It provides a secure fit and is ideal for areas where stability is essential.

2. Self-Adhesive

These tiles come with a peel-off backing paper that sticks directly to the subfloor. Some self-adhesive tiles have overlaps to stick to each other instead of the subfloor, making installation simpler.

3. Sheet Vinyl

Sheet vinyl can be installed using methods like permanent bond, releasable bond or loose lay. We recommend having sheet vinyl floors professionally installed but if you plan to install the flooring yourself, be sure to seek luxury vinyl sheet or resilient installation instructions from the flooring manufacturer.

4. Click System

Click system tiles use a mechanical jointing system, similar to tongue-and-groove, allowing them to float over the subfloor without glue. This method is quick to install and offers excellent stability.

Expert Vinyl Flooring Installation: Ensuring Perfect Preparation and Flawless Finish with Clarkes Carpets

Vinyl flooring installation is a meticulous process that begins with thorough preparation and understanding of the product’s construction. At Clarkes Carpets, we provide high-quality vinyl flooring options and expert advice to ensure your installation is seamless and your floors are stunning. Visit us today to explore our range and learn more about the perfect installation techniques for your space.